High Pin Count/High Volume

A production volume test fixture with interchangeable test cassettes. The interchangeable test cassettes provide the ability for one fixture base to support a variety of units under test.

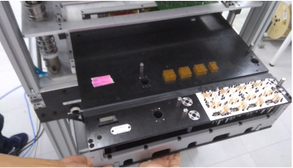

Manual High Pin Count Test Fixture

A production volume test fixture with interchangeable test cassettes. The interchangeable test cassettes provide the ability for one fixture base to support a variety of units under test.

Applications and Features

-

Mid volume (1K-5K+/month)

-

Mid to high pin count (<1,000) test

-

Where higher precision guiding and clamp push-finger positioning is required

-

Interfacing to larger test systems (mass termination such as Pylon or VPC)

-

Test hardware or acquisition boards can be built into the base unit

-

Multi-product test with one test base

-

Multiple interchangeable product specific cassettes

Vacuum Fixture

Vacuum Fixtures are normally used for fully assembled board test and are usually seated onto a system specific receiver to provide a quick interchange. These can have single or double-sided probing. For maximum probe accuracy top and bottom plate alignment is crucial. Elektrotek use a double pin and polymer bushing configuration to ensure accurate guiding. Vacuum fixtures can have very high pin count and are generally the most accurate probing method as they can be built to a very high engineering standard.

Applications and Features

• Mid to high volume (5K+/month) & high pin count (2,500+)

• Where higher precision guiding and clamping is required

• Where top and bottom probing is required with fine pitch probes

• Interfacing to larger test systems with quick change over required

• ICT (In Circuit Test) or MDA (Manufacturing Defect Analysis) Test System Connection

Pneumatic Test Fixture

There are endless fixture configurations where pneumatic actuation is used, this can range from a simple connector on a slide, to an alternative means of actuation for mechanical or vacuum style fixtures.

Most pneumatic fixtures are similar in function to the Vacuum Fixture, except that a pneumatic press is used to push the board under test onto the test probes. Normally these fixtures are easier than the vacuum type to install as they do not require a powerful vacuum air source and are generally more flexible in the way they can get access to a UUT. This type of fixture can be used to connect to a UUT from different sides and angles.

In Line Test fixture

Elektrotek’s In-Line Board Handler fixturing meets the high-performance requirements associated with high-volume production. The big advantage is high throughput and elimination of operator errors such as mix up of the PASS/FAIL boards. Some can have a dual stop feature added, which allow a second position on the same fixture for parallel programming or Functional Test.

Applications and Features

-

Dual sided probing

-

LED sensing probes

-

Switch probes

-

High Volume (20K+/month) & High Pin Count (2,500+) ICT or MDA Test

-

High Volume (20K+/month) & Mid Pin Count with Functional Test and Programming integrated

-

Where higher precision guiding and clamping is required

-

Test cell or cells as part of an automated assembly line

-

Offline systems using automated handlers and PCB stacking racks

_edited_edited.jpg)